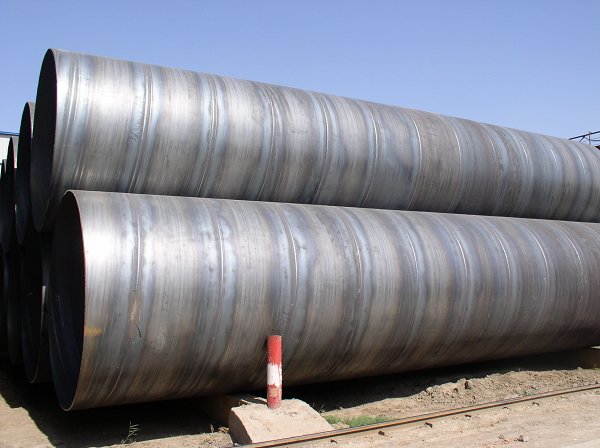

Our manufacturing facility for helical submerged arc welded (HSAW) pipes employing electrical fusion welding is a state of

the art facility to produce quality pipes. The spiral welded pipe mill is BYARD SPIRALMILL sdn. Bhd. make, along with the

other equipments provide the company with the superior technology and competent to deal with the best in the industry.

The pipe plant has a capacity to produce 70,000 MT of pipe per annum and can produce spirally welded pipes in the range of 18

inches (457 mm) to 100 inches (2540 mm) with maximum wall thickness of 1 inch (25.4 mm) & pipe length of 6 meters to 13

meters as per client’s requirement confirming to various national as well as international quality standards.

The uniqueness of our plant is that the whole unit is mobile & can be moved to the project site. This feature benefit our clients not only by reducing the transportation cost of pipes but it reduces the damage of pipes during transportation & also helps timely execution of the project by continuous & dedicated supply of pipes for the particular project.

Spiral pipes are produced from hot rolled coils produced in steel plant. All the incoming coils are verified for its chemistry &

mechanical properties as per the test certificate received from the steel plant tomeet specification requirements.

The Spiral Pipe manufacturing process involves setting of the mill entry line as per the calculated angle with respect to centre

line of pipe & forming cage to the required diameter. The coils are opened, leveled in leveler & end sheared to facilitate

joining of incoming & outgoing coils & joined by Submerged Arc Welding to maintain production continuity. Subsequently

it is guided & its edges are milled to get the desired edge. It is then formed at the forming table on the principle of three roll

bending to get the required diameter & auto SAW welded from inside. Since the strip is being fed continuously inside welding operation is also continuous. At about 180 degree phase, continuous outside auto SAW welding is carried out so that string of formed pipe is welded from both sides. It is then cut to the required length by Plasma equipment at the cut off equipment. Individual pipe is serially numbered for its traceability. During forming & welding, weld gap at inside welding is maintained by gap control unit to get adequate fusion from inside.

All the pipes are then inspected from inside as well as outside to find defect in the weld or body, diameter, forming defects etc. Pipes requiring rectification are manually rectified by manual welding &/or grinding depending on the nature of defect. Pipe ends are then beveled. Each pipe is then hydrostatically tested as per the calculated pressure; it is then inspected before offering to the customer’s inspectors. Accepted pipes are then paint stenciled as per the requirement before shifting it to the storage yard & subsequent dispatch.

We can manufacture Spirally Welded SAW Pipes in the following range:

Stockist and Dealers of ...

Pipe Prodution, Pipe Producer, pipe godown, pipe inventory, pipe manufacturing process, Pipes Stockyard, ANSI/ASME pipe Dealers, Bimetallic tubes Dealers, Boiler tubes Dealers, Capillary tubes Dealers, Chemical injection lines Dealers, Coiled tubing Dealers, Composite tubes Dealers, Condenser tubes Dealers, Ethylene furnace tubes Dealers, Evaporator tubes Dealers, Finned tubes Dealers, Flowline piping Dealers, Furnace tubes Dealers, Gasoline direct injection (GDI) tubes Dealers, Heat exchanger tubes Dealers, High-pressure tubes Dealers, High-temperature tubes Dealers, Hydraulic tubing Dealers, Instrumentation tubing Dealers, ISO/EN tubes Dealers, Lance tubes Dealers, Mechanical tubing Dealers, Medical tubes Dealers, Muffle tubes Dealers, Nuclear fuel tubes Dealers, Nuclear steam generator tubing Dealers, Precision tubes Dealers, Production tubing (OCTG) Dealers, Recuperator tubes Dealers, Reheater tubes Dealers, Riser tubes Dealers, Scrubber tubes Dealers, Steam generator tubes Dealers, Stripper tubes Dealers, Subsea tubes Dealers, Superheater tubes Dealers, Thermocouple tubes Dealers, Titanium tubes Dealers, Umbilical tubes Dealers, Zirconium tubes Dealers, ANSI/ASME pipe Stockist India, Bimetallic tubes Stockist India, Boiler tubes Stockist India, Capillary tubes Stockist India, Chemical injection lines Stockist India, Coiled tubing Stockist India, Composite tubes Stockist India, Condenser tubes Stockist India, Ethylene furnace tubes Stockist India, Evaporator tubes Stockist India, Finned tubes Stockist India, Flowline piping Stockist India, Furnace tubes Stockist India, Gasoline direct injection (GDI) tubes Stockist India, Heat exchanger tubes Stockist India, High-pressure tubes Stockist India, High-temperature tubes Stockist India, Hydraulic tubing Stockist India, Instrumentation tubing Stockist India, ISO/EN tubes Stockist India, Lance tubes Stockist India, Mechanical tubing Stockist India, Medical tubes Stockist India, Muffle tubes Stockist India, Nuclear fuel tubes Stockist India, Nuclear steam generator tubing Stockist India, Precision tubes Stockist India, Production tubing (OCTG) Stockist India, Recuperator tubes Stockist India, Reheater tubes Stockist India, Riser tubes Stockist India, Scrubber tubes Stockist India, Steam generator tubes Stockist India, Stripper tubes Stockist India, Subsea tubes Stockist India, Superheater tubes Stockist India, Thermocouple tubes Stockist India, Titanium tubes Stockist India, Umbilical tubes Stockist India, Zirconium tubes Stockist India,

main country:

| main country:

| City

| City

|

Click on the Products Below to Learn More. All qualities and sizes, request your quote online!

| |||||

|  |  |  |  |  |

|  |  |  |  |  |

Contact With Us |  |